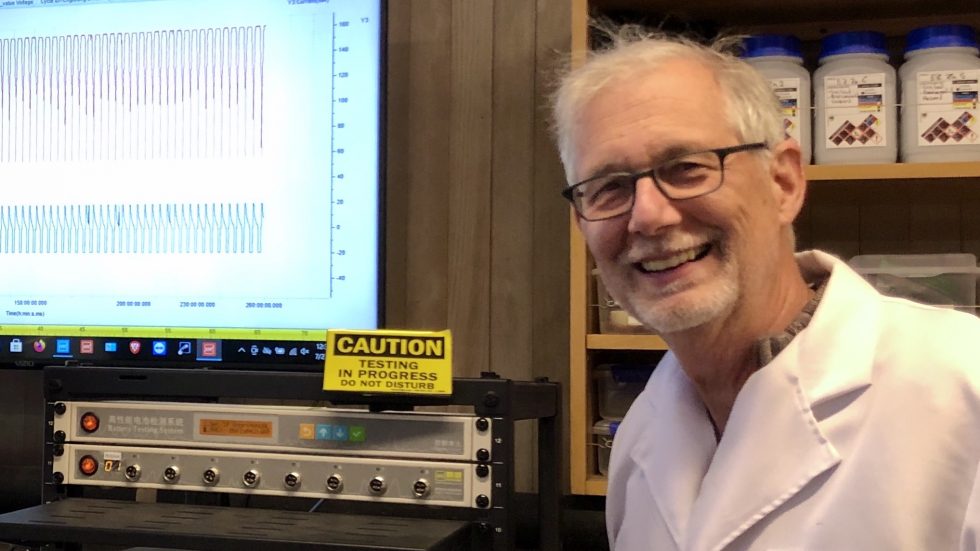

Advanced Battery Developer Enzinc Wins Global Automotive and Mobility Innovation Challenge

Advanced technology repurposes existing lead acid manufacturing infrastructure to expedite the deployment of better batteries

RICHMOND, Calif.: Enzinc Inc., an advanced rechargeable zinc battery developer, was selected for a competitive $1.8 million California Energy Commission (CEC) BRIDGE award to further develop its zinc batteries for stationary and mobility uses. After approval, the proceeds, along with $1.0 million of matching funds, will be used to design and test a long duration stationary battery and build out a pilot anode manufacturing line.

“If we are to electrify everything, we need batteries that use easily-sourced materials and can be scaled rapidly. Being selected for BRIDGE shows the rising awareness that we can’t place all of our energy storage bets on lithium technologies,” said Michael Burz, founder and CEO of Enzinc. “Today’s $60 billion lead-acid battery market can play a larger role in the energy transition by converting existing factories to use Enzinc’s drop-in technology and make more powerful, higher margin and longer lasting batteries.”

Batteries with Enzinc’s zinc microsponge anode’s safe, non-flammable materials will make it ideal for stationary energy storage inside homes and commercial buildings and adjacent to critical energy infrastructure. Additionally, it will be ideal for mobility including e-bikes, e-scooters, electric delivery vehicles and other electric vehicles with moderate ranges, as well as be able to replace the lead acid battery that all vehicles use for starter motors and other systems.

“The EPIC programs available at each stage of a clean energy company’s development and commercialization are creating a vibrant and innovative industry in California,” Burz said. “We are honored to have been a recipient of these vital awards at key points in our company’s growth and to be selected for BRIDGE.”

The Bringing Rapid Innovation Development to Green Energy, or BRIDGE, awards are funded by the Electric Program Investment Charge (EPIC) program, which will grant up to a total of $57.3 million over four rounds. Enzinc and four other companies were selected for the proposed final round of funding, contingent on final approval at a CEC business meeting.

Previously, Enzinc has received CalSEED Phase I and II awards, together worth $600,000, and a $292,000 CalTestBed voucher for product testing. The selection follows Enzinc’s announcements that it has formed an Industry Advisory Group with global leaders in battery production, use and recycling, and that it won the Global Automotive and Mobility Innovation Challenge, GAMIC, at the SAE International World Congress Experience.